The I/O Test Assembly (IOTA) provides a breakout, patch and test facility for the 10-pin shrouded I/O connector used with various BOBZ project boards and modules.

The assembly has two shrouded 2x5 IDC connectors, one for input and one for output. Normally, the input connector connects to project I/O with a short ribbon connector. The output connector normally connects to application I/O through a short ribbon cable.

The two connectors each land on a patch block. These blocks can be connected together to provide a pass-through connection between the pins of the two I/O connectors. By removing jumpers, I/O pins can be isolated so that they do not pass-through but terminate on the board.

The I/O pins, whether configured for pass-through or isolated operation, can be patched to on-board test LEDs, pullup, switch, power or ground. There are four test LEDs, each of a different color, that can be patched to the I/O pins of the input and output connectors. A test switch can also be selectively patched to the I/O pins.

The power and ground pins of the input and output connectors are also available as stake-pin test points. The connector ground pins are connected together and wired to a 1x8 stake-pin array. The 3.3 Volt power from the I/O connectors are individually connected to a 1x2 stake-pin jumper. These power pins can remain isolated or connected together with a Berg jumper, depending on the application's power configuration.

Page ii

(BLANK)

Page 1

Page 2

For convenient reference and improved readability, we recommend that you download a high resolution IOTA schematic.

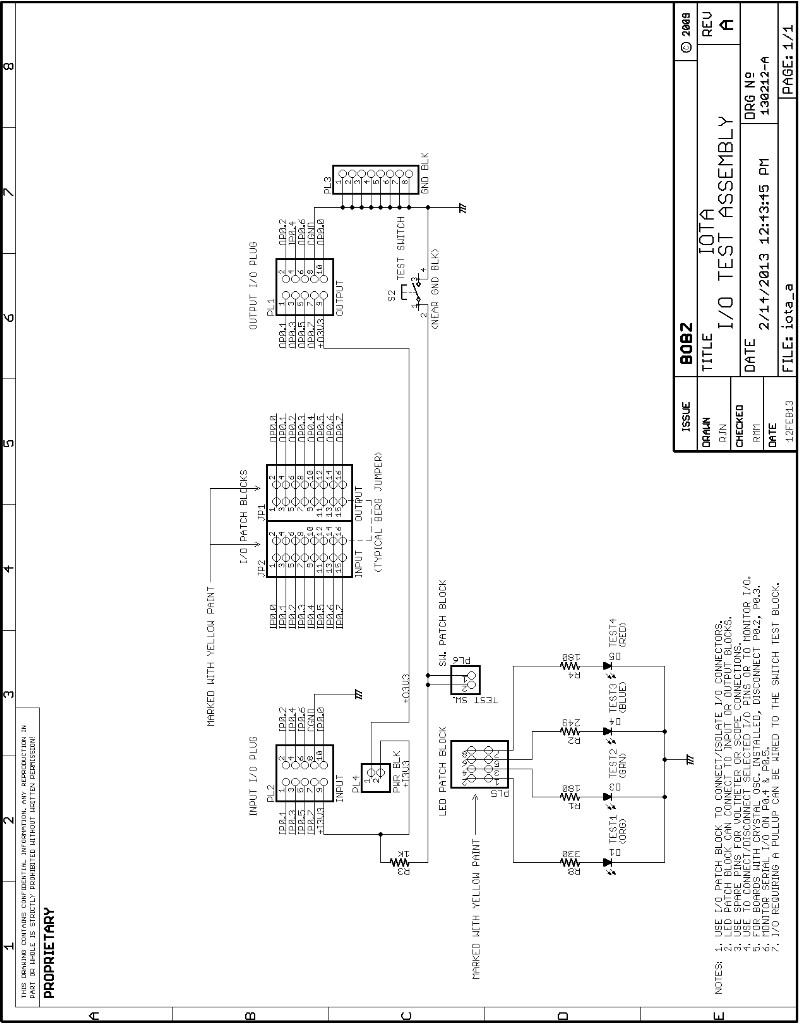

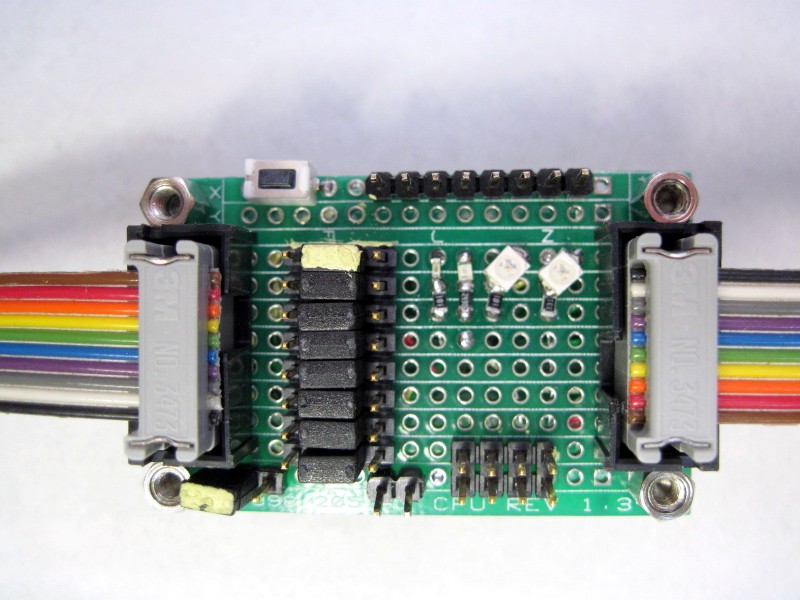

Photo 1 shows a closeup photo of the I/O Test Assembly. Schematic 1 shows the IOTA board wiring. The following descriptions refer to these two figures.

The I/O Test Assembly (IOTA) provides a breakout, patch and test facility for the 10-pin I/O connector used with various BOBZ project boards and modules.

The assembly has two shrouded 2x5 IDC connectors, one for input and one for output. Normally, the input connector is connected to project I/O with a short ribbon connector. The output connector typically connects to application I/O with another short ribbon cable. The two connectors each connet to a central patch block. These blocks can connect together with Berg jumpers to provide a pass-through connection between the pins of the two I/O connectors. By removing jumpers, I/O pins can be isolated from each other so that they do not pass-through from the input to the output.

The I/O pins, whether configured for pass-through or isolated operation, can be patched to on-board test LEDs, a pullup, switch, power or ground. There are four test LEDs, each of a different color, that can be patched to the I/O pins of the input and output connectors. A test switch can be patched to one of the I/O pins or LEDs.

The power and ground pins of the input and output connectors are also available as stake-pin test points on the assembly. The grounds connect together and wire to a 1x8 stake-pin array. The 3.3 Volt power connections from the I/O connectors are individually connected to terminals of a 1x2 stake-pin jumper. These pins can remain isolated or connected together with a Berg jumper, depending on the application's power configuration.

The IOTA board can be used with the BOBZ Breakout Board to provide both stake-pin and screw down connections in addition to I/O monitoring.

The Operation Section describes various connection options in more detail.

Page 3

Schematic 1 -- IOTA I/O Test Assembly Schematic

Page 4

Photo 1 -- IOTA Test Assembly

Page 5

The most basic configuration is for one-to-one pass through. In this configuration, Berg jumpers are installed on all eight of the pin pairs at the center of the two I/O Patch Blocks, JP2 and JP1. The I/O Patch Blocks are shown in Photo 1 on the left half of the board, near the Input I/O Plug. The Input I/O Plug is located on the left side of the board and the Output I/O Plug is located on the right side of the board. Note that the "Input" and "Output" designation is arbitrary: the connections to the I/O plugs are identical.

The photo shows the board configured for pass-through operation with all eight of the Berg jumpers installed. Note that only one of these jumpers is shown on the schematic to avoid drawing clutter. The Patch Block connections for port zero, pin zero, P0.0, is at the top of the Patch Block. The Berg jumper for this connection is painted yellow.

The port connections are in ascending order from top to bottom of the block. For example, the four connection points for P0.7 (pin 7 of the I/O connectors) is near the bottom of the board. Note that, when connected for pass-through operation, each I/O connection has two pins availble for patching to on-board I/O or external equipment and circuitry.

When configured for pass-through operation, the input and output connectors, PL2 and PL3, respectively, are connected together so that the assembly acts as a piece of cable: PL2 pin 1 connects to PL3 pin 1, PL2 pin 2 connects to PL3 pin 2, etc. Thus, the assembly can be used to bridge between a project board and an application board as if they are connected with a ribbon cable while allowing signal pins to be monitored with a scope, voltmeter or test LEDs.

To monitor a line with a test LED, connect a free pin on the I/O Patch Blocks (PL2/PL3) to one of the pins on the LED Patch Block (2x4 stake pins array at the bottom middle of the board). Note that there are two pins dedicated to each LED on the block so that the patched pin is not lost for an off-board connection. Thus, when pins are configured for pass-through operation, there are two stake pin connections available for off-board monitoring, even with a test LED connected.

Page 6

The pins of the input and output connectors can be isolated from each other by removing the Berg jumper for the selected pin. When a pin pair is isolated, the isolated JP2 and JP3 pins can be independently connected to the on-board test facilities such as the LEDs, switch, pullup (switch pin), power or ground. The isolated configuration can be useful for the following:

The following sections describe some of the the above configurations in more detail.

Four on-board test LEDs are shown in Photo 1 just above the middle of the right half of the board (the four white rectangles). The four test LEDs are different colors to help identify signal connections.

The LEDs can be individually connected to I/O Patch Block terminals with socket-to-socket wire jumpers. These jumpers are commonly available from vendors such as Adafruit. The LED jumper connections are made between unused JP2 and JP3 pins and LED patch block pins. Each LED is wired to two patch block pins so that connecting an LED does not result in a lost I/O connection point. The LED Patch Block is shown in Photo 1 near the bottom middle -- it is a 2x4 stake pin header array.

To test the LEDs, connect the LED terminals to a "hot" pin of the Power Block, PL4. Note that both power block pins may not be connected to +3.3 Volts, depending on whether or not the output connector has a power feed to the board (e.g., from an application board). Normally, the terminal connected to the input connector is powered and available for LED testing.

The LED connections are for processor outputs that "source" current. Thus, the Test LEDs light when processor outputs is high. The LEDs indicate processor outputs configured for push-pull or for open-drain with a pullup. For high-value pullups, the LEDs may not light or will light dimly.

The values for the current limiting resistors shown in the Schematic were adjusted for approximately even brightness, according to the individual forward voltage drops and the LED types on hand (i.e., some were high efficiency, some were not). The limiting resistors were also sized so that the LED currents were each under 10 milliamperes to reduce the load on a 78L33 regulator (i.e., the typical power source from an AGEN board).

Page 7

The Test Switch is shown in the upper left hand corner of Photo 1. The Switch Patch Block, PL6, is located on the bottom middle of the board, just to the left of the LED Patch Block. A socket to socket jumper wire can be connected to one of the free I/O Patch Block pins. Normally, the input connected to the test switch is isolated (i.e., remove the Berg jumper).

The Test Switch pins connect through a 1K resistor to the +3.3 Volt power from the input connector. This allows the Test Switch pins to be used to pull up an input or open-drain output to the supply voltage.

A Test Switch pin can be wired to one of the four Test LEDs. When connected this way, the Test Switch pullup reduces the current through the selected LED so that its brightness is reduced. Pressing the switch extinguishes the LED. This connection, when used with a pin configured as an input, will probably work but note that the input voltage will be reduced to slightly more than the LED forward voltage (e.g., 1.6 Volts for the red LED). If possible, use the blue LED for this kind of connection.

Two pins provide separate connection points for the power pins of the input and output connectors. Normally, the pin connected to the input side will have 3.3 Volts supplied from a project board. The pin connected to the Output I/O Plug may not have +3.3 Volts supplied from the application board. To supply power from the Input I/O Plug to the Output I/O Plug, connect a Berg jumper between the two Power Block pins. As shown in Photo 1, the Power Block is on the far left bottom of the board. The top of its Berg jumper is painted yellow. The jumper is shown in its "disconnected" position.

Eight ground connection points are availble at the Grounding Block, PL3. This is the 1x8 stake pin header on the top edge of the board, as shown in Photo 1. These pins can be used to jumper I/O pins to ground or to provide an off-board ground connection for instruments such as a voltemeter or oscilloscope.

Use one of the Test LEDs to determine which of the Power Block pins is connected to +3.3 Volts by installing a jumper between the selected power pin and one of the pins of the LED Patch Block.

Some of our I/O connections between project and application boards is implemented with a 10-wire ribbon cable with a 10-pin socket on each end and a 10-pin socket in the middle of the cable to provide access to each of the signal wires. For boards connected this way, IOTA can connect to the middle connector with a short ribbon cable. In this configuration, the output connector is left unconnected. An IOTA connected in this way provides a convenient way to monitor I/O lines. The board not only provides additional test points but also allows connections to be monitored with LEDs.

Using the board in this "monitor" configuration saves having to mount test LEDs and a test switch on project or application boards.

Page 8

The I/O connectors are placed at the left and right sides of the board. The connectors are arranged so that the center key of the shroud faces outward. Thus, pin 1 corresponds to the brown wire in the ribbon cable. The off-center key on the back of the shroud is not used. The ribbon cables are typically short (e.g., 2 inches) to reduce cabling length between project and application boards. Ribbon cable wire coding is the same as that used for resistor color coding: brown=1, red=2, black=0, etc. Port pins are wired to corresponding IDC connector pins. For example, port pin 0 (P0.0) is wired to pin 10 for "zero" and port pin 1 (P0.1) is wired to pin 1. Power connects to pins 8 and 9 which do not correspond to any processor I/O.

The LEDs are wired to 0805 SMT limiting resistors by bridging the resistors across 0.1-spaced solder pads. The LEDs were selected from our stock of SMTs. Thus, there are three different sizes. The two 1206 LEDs (orange and green) mount crosswise. The 0805 LED (blue) mounts vertically between two pads, as does the 0603 LED (red). The "top" side of the LEDs connect to the 1x8 ground block at the top of the board. The resistor ends each connect to a 2-pin row of the 2x4 LED Patch Block.

The I/O patch blocks mount near the "input" connector. This minimizes the wire length from the I/O connector to the block. This is important for project boards using a crystal: disconnecting pins 2 and 3 minimize wire capacitance across the crystal.

Most of the rest of the I/O connection points are arranged on the board wherever they fit. The two-pin Power Block mounts just below the I/O connector. The Test Switch mounts on the left top of the board so that there is enough room around it to accomodate the end of a finger. The Switch Patch Block was placed at the bottom right of the I/O Patch Block and to the left of the LED Patch Block, mostly because it didn't seem to logically fit anyplace else.

The ground block was placed on the edge of the board to accomodate scope ground clips and ground wires that would be awkward if placed in the center of the board.

Not shown in the photo is a bottom plate to protect the bottom-side wiring. The plate is another piece of perforated board mounted to the top board with some 4-40 standoffs and screws.

A PCB of this board may be available, depending on demand and usefulness.

Initial release |